Plate heat exchangers are vital for maintaining efficiency and reliability in industries ranging from HVAC to chemical processing, food and beverage, and marine engineering. Every component, from gaskets to plates and accessories, plays a crucial role in keeping the system running smoothly. Choosing the right Plate Heat Exchanger Spare Parts is more than a budget decision—it impacts thermal efficiency, system longevity, and maintenance frequency. Understanding the differences between OEM and aftermarket spares helps plant engineers and maintenance teams make informed choices that safeguard operations and reduce unexpected downtime.

Plate Heat Exchanger Spare Parts Explained

What Are Plate Heat Exchanger Spares?

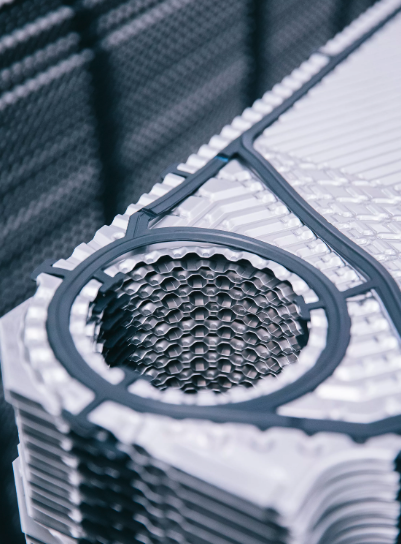

Plate heat exchanger spares are the components designed to keep your system running smoothly. Gaskets prevent leaks by sealing the space between plates. Replacement plates restore thermal capacity if the originals are worn or damaged. Other accessories, like frame fastenings, sealing strips, and specialized cleaning tools, help maintain the entire system. Without these spares, downtime increases, efficiency drops, and maintenance costs skyrocket.

These spares are used across multiple industries. For example, in chemical processing, leaks can cause contamination or chemical loss. In marine systems, corrosion-resistant plates prevent saltwater damage. Even small gaskets or sealing strips can make the difference between reliable operation and emergency shutdown.

Why Spare Parts Matter

The impact of spare parts goes beyond simple replacement. They:

Minimize downtime: Quick replacement keeps operations on schedule.

Maintain thermal efficiency: Proper gaskets and plates ensure optimal heat transfer.

Extend equipment lifespan: High-quality spares reduce wear and tear.

Reduce maintenance costs: Prevents repeated repairs and emergency interventions.

Imagine a plant where a worn gasket fails. The fluid leaks, heat transfer drops, and production slows. That’s where proper spares save time, money, and headaches.

OEM Plate Heat Exchanger Spares

What Are OEM Spares?

OEM spares are produced by the original equipment manufacturer or certified service providers. They are built to match exact design specifications, materials, and tolerances of the original heat exchanger. This ensures each part fits precisely, works reliably, and maintains the intended performance of the system. Think of it like replacing a phone screen with the original component rather than a generic copy—it simply works better, lasts longer, and avoids unexpected failures. Using OEM spares means you get parts engineered specifically for your equipment rather than a “one-size-fits-most” solution.

Advantages of OEM Spares

OEM spares provide several advantages that directly impact system reliability and maintenance. First, they offer a perfect fit, engineered for specific plate heat exchanger models, which reduces the risk of leaks and operational issues. The materials used are highly durable; stainless steel plates resist corrosion, while elastomer gaskets handle high temperatures and pressures without deformation. OEMs often maintain a reliable supply of critical parts, so replacements can be sourced quickly, reducing downtime in emergencies. Beyond parts, OEM providers also deliver technical support, including troubleshooting, guidance on installation, and maintenance advice, which ensures the system continues to operate efficiently.

Cost and Value

Although OEM spares usually come at a higher upfront cost, they deliver significant long-term value. By reducing the frequency of repairs, minimizing unexpected downtime, and extending the lifespan of heat exchangers, these parts often pay for themselves over time. For plants with critical operations, investing a little more now can prevent costly interruptions later. OEM spares also offer predictable lifecycle costs, giving engineers and plant managers confidence in budgeting and maintenance planning. In essence, they provide reliability, peace of mind, and protection against unforeseen operational losses.

Aftermarket Plate Heat Exchanger Spares

What Are Aftermarket Spares?

Aftermarket spares are produced by third-party suppliers rather than the original equipment manufacturer. They are typically designed to “fit most” plate heat exchanger models rather than match exact specifications. While they can work in certain applications, they usually lack the precise engineering and quality control that OEM parts provide. They are often chosen because of their lower cost, but using them comes with trade-offs that plants and engineers must carefully consider before purchase.

Advantages

Aftermarket spares can offer some practical benefits for plants, especially when budget constraints are a concern. They generally cost less upfront, helping facilities manage expenses in the short term. In some regions, aftermarket parts may also be easier or faster to source than OEM components, which is useful when urgent replacements are needed. Additionally, they can serve as temporary solutions for non-critical systems, allowing plants to continue operations while waiting for permanent or OEM parts.

Drawbacks

Despite these benefits, aftermarket spares come with several potential drawbacks. Compatibility issues can occur, leading to leaks or reduced heat transfer efficiency. Their lifespan is often shorter than OEM parts, which may result in more frequent replacements and higher cumulative costs. Technical support is usually limited or unavailable, leaving plant engineers responsible for troubleshooting and installation issues. There is also a risk of hidden costs caused by downtime or repeated maintenance. For instance, using an aftermarket gasket in a high-pressure chemical system could cause a leak, halt production, and eliminate any initial savings. Therefore, careful assessment is essential before relying on aftermarket spares for critical equipment.

| Feature | OEM Spares | Aftermarket Spares |

| Cost | Higher upfront | Lower upfront |

| Compatibility | Exact fit | May vary |

| Lifespan | Long-lasting | Shorter |

| Technical Support | Full guidance | Limited |

| Inventory & Lead Time | Ready stock, fast delivery | Variable, may wait |

| Downtime Risk | Low | Higher |

| Warranty | Included | Rarely included |

![Plate Heat Exchanger Spare Parts Plate Heat Exchanger Spare Parts]()

Key Considerations for Choosing Spares

Cost vs Long-Term Value

Non-OEM parts may save money upfront but can increase long-term costs due to maintenance, downtime, and reduced efficiency. OEM spares require higher initial investment but deliver predictable lifecycle cost, reliability, and fewer surprises.

System Performance & Compatibility

Precision fit matters. A gasket or plate that doesn’t match exactly can reduce heat transfer efficiency, cause uneven wear, or damage other components. OEM parts maintain system integrity. Aftermarket parts may be “close enough,” but small deviations add up over time.

Availability & Lead Time

| Type | Inventory | Lead Time | Downtime Risk |

| OEM | Stocked, ready | Short | Low |

| Aftermarket | Variable, limited | Longer | Higher |

Maintenance & Support

OEM providers usually offer installation guidance, troubleshooting, and warranties. Aftermarket suppliers focus on parts supply, rarely providing end-to-end solutions. When issues arise, OEM technical support can save hours or even days of downtime.

Safety & Compliance

OEM spares adhere to strict industry standards and undergo quality checks. Aftermarket parts may comply, but testing is inconsistent. For industries like food processing or chemicals, ensuring compliance isn’t optional—it’s critical.

Ensuring Quality No Matter the Choice

Verify Supplier: Always check the credibility of your parts supplier. Look for proper certifications, customer references, and online reviews. A trusted supplier ensures that the spares meet industry standards and reduces the risk of receiving low-quality or incompatible parts. Reliable suppliers also provide documentation and support, giving you confidence in your purchase.

Material Standards: Pay close attention to the materials used in both plates and gaskets. Stainless steel quality affects corrosion resistance, and elastomers must withstand high temperatures, pressures, and chemical exposure. Ensure that machining and tolerances are precise, and perform tests for leaks, pressure limits, and thermal performance to guarantee the parts will perform safely and efficiently in your system.

Installation Practices: Correct installation is just as important as part quality. Gaskets should be aligned properly, plates handled carefully to avoid scratches or deformation, and all fastenings torqued according to manufacturer specifications. Regular inspections after installation help detect early wear or misalignment. Proper procedures can prevent many operational issues that material quality alone cannot solve.

Proper installation, combined with careful supplier selection and material verification, often prevents problems before they occur, ensuring your heat exchanger operates efficiently and reliably.

FAQ

Q1: What is the difference between OEM and aftermarket plate heat exchanger spares?

A1: OEM spares are manufactured by the original equipment manufacturer or certified providers and match exact design specifications, while aftermarket spares are made by third-party suppliers and are generally designed to “fit most” models, which may lead to compatibility differences.

Q2: Are OEM spares more expensive than aftermarket spares?

A2: Yes, OEM spares usually have a higher upfront cost, but they provide long-term value through improved reliability, longer lifespan, and reduced downtime.

Q3: Can aftermarket spares be used for critical heat exchanger systems?

A3: Aftermarket spares can be used for temporary or non-critical applications, but they may not provide the precise fit, durability, or technical support required for high-value or critical systems.

Q4: How do OEM spares improve system reliability?

A4: OEM spares ensure a perfect fit, use durable materials like stainless steel and high-quality elastomers, and come with technical support, reducing leaks, wear, and unplanned downtime.

Conclusion

Selecting high-quality Plate Heat Exchanger Spare Parts ensures your system operates at peak performance, minimizes downtime, and extends the lifespan of critical equipment. OEM parts offer precision, durability, and technical support, while aftermarket spares may be cost-effective but come with trade-offs in compatibility and reliability. For companies seeking dependable solutions for all types of plate heat exchangers, Jiangsu Yuanzhuo Equipment Manufacturing Co., Ltd. provides a comprehensive range of high-quality spare parts, expert technical guidance, and rapid support to keep operations running efficiently. Partnering with a trusted supplier guarantees long-term performance and peace of mind for every plant or fac