How Do You Size A Plate Heat Exchanger?

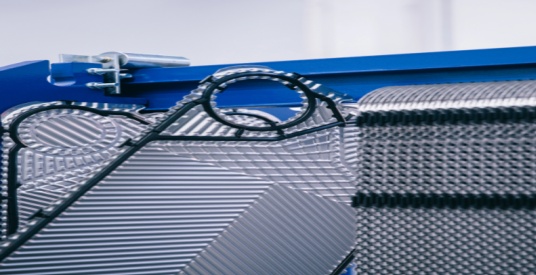

Plate heat exchangers (PHE) are widely used in industries such as chemical processing, food and beverage, HVAC, and energy production due to their efficiency in transferring heat between two fluids. Unlike traditional shell-and-tube heat exchangers, PHEs consist of multiple thin plates that are stacked together, creating narrow channels for fluid flow. This design enables excellent heat transfer performance and compactness.

More >>

What Does A Plate Heat Exchanger Do?

In many industrial applications, managing heat is a critical aspect of maintaining operational efficiency. One highly effective solution for heat transfer is the plate heat exchanger (PHE). This device plays an essential role in various industries, including HVAC, chemical, pharmaceutical, food and beverage, and power generation. By utilizing a series of plates to transfer heat between two fluids, a plate heat exchanger allows for efficient thermal energy exchange while maintaining compactness and flexibility.

More >>

What Is The Max Temp for Plate Heat Exchangers?

Plate heat exchangers (PHEs) are widely used in a variety of industries due to their efficiency, compact design, and high heat transfer capacity. Whether used in food processing, chemical industries, HVAC systems, or even power generation, the performance of a plate heat exchanger is crucial to the overall system’s efficiency. One of the key considerations when selecting a plate heat exchanger is its maximum operating temperature. This article explores the maximum temperature limits for plate heat exchangers, the factors influencing these limits, and how to ensure safe and optimal operation.

More >>