· Product Introduction

![ZL20C-(2) ZL20C-(2)]()

· Model

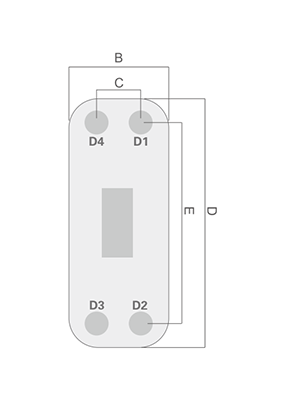

ZL190 |

B(mm) 303 | C(mm) 179 | D(mm) 695 | E(mm) 567 | Thickness ( mm ) 13+2.3N |

Max flowrate ( m3/h ) 100 |

Weight ( Kg ) 12+0.61N Design pressure ( Mpa) 1.6/2.1/3 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

High-pressure performance heat exchangers are critical components in various industries where they operate under demanding conditions of elevated temperature and pressure. Here are some applications where high-pressure heat exchangers are typically utilized:

Power Generation: In power plants, especially those using supercritical CO2 Brayton cycles, high-pressure heat exchangers are essential for efficient energy conversion processes .

Nuclear Engineering: They are used in next-generation nuclear reactors and nuclear hydrogen production facilities, where they can withstand the extreme conditions of high temperature and pressure .

Chemical Processing: High-pressure heat exchangers are vital in chemical plants for processes that require heat exchange under high-pressure conditions to prevent the fluid from flashing or to maintain the desired reaction conditions .

Petroleum Refining: In refineries, they are used to handle high-pressure streams, such as in catalytic crackers and hydrotreaters, where high pressures are necessary to improve reaction kinetics and product yields .

Aerospace: High-pressure heat exchangers are used in aerospace applications, including spacecraft thermal management systems, where they must operate reliably in the vacuum of space and withstand the thermal stresses associated with launch and re-entry .

Renewable Energy Storage: They are employed in next-generation renewable energy storage processes, such as concentrated solar power, where high pressure and temperature can improve the efficiency of energy storage and retrieval .

Waste Heat Recovery: In systems designed to capture and utilize waste heat, high-pressure heat exchangers can effectively transfer thermal energy from exhaust gases or other waste streams to a useful heat sink .

High-Temperature Fuel Cell Systems: These systems benefit from the use of high-pressure heat exchangers to manage the thermal loads and maintain the necessary operating conditions for the fuel cells .

Flue Gas Conditioning: In flue gas cleaning processes, high-pressure heat exchangers can preheat the gases, improving the efficiency of downstream pollution control equipment .

The design, material selection, and operational parameters of high-pressure heat exchangers are crucial for their performance and reliability in these applications. Advanced materials such as silicon carbide, which can operate in extreme environments with high power densities, are being investigated for use in these heat exchangers to address the challenges posed by high-temperature, high-pressure thermodynamic cycles